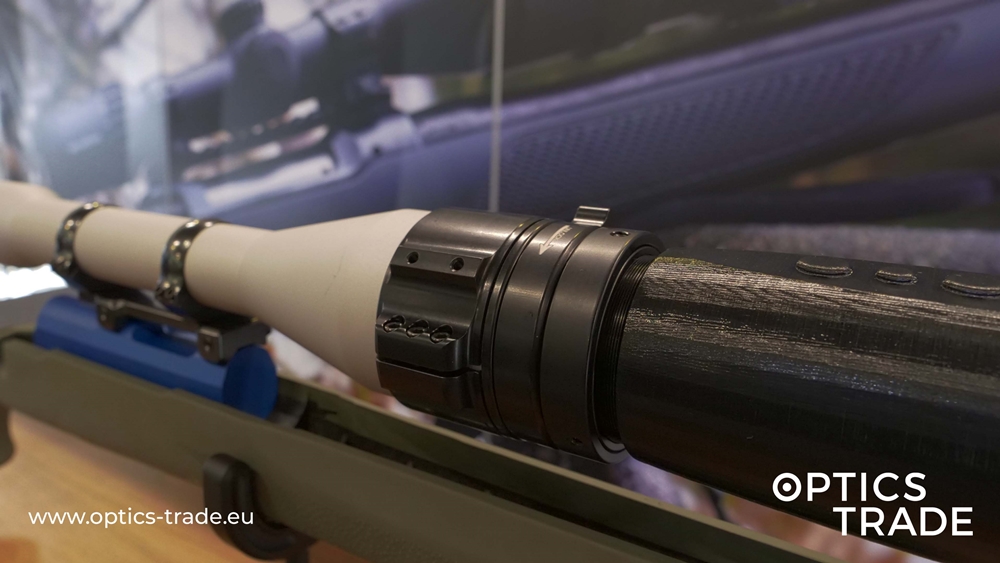

Proper mounting of optics is one of the key factors that affect its precision and reliability. Each component, from the base, Picatinny/Weaver rails to the rings, must be properly adjusted, and the screws must be mounted with the appropriate tightening force (torque).

Recommended screw tightening forces

To ensure optimal stability and reliability, the manufacturers prescribe recommended torque values of screw tightening. Prescribed values can be ensured only by using the proper tools – a torque driver to mount optics. There are quite a lot of manufacturers of such tools on the market (Wheeler, Vortex, Nightforce, Weaver, etc.). They feature an adjustable torque scale, displayed in inch/pounds. The European unit for measuring torque is the Newton meter (Nm).

In need of proper mounting tools?

The recommended torque values for tightening screws of individual assemblies for mounting optics given in in/lbs and Nm are:

- when mounting a Weaver/Picatinny rail on the action, 15-55 in/lbs or 1.69-6.21 Nm (Badger 15 in/lbs or 1.69 Nm), Warne and Nightforce 25 in/lbs or 2.82 Nm, Vortex 55 in/lbs or 6.21 Nm);

- when mounting rings on a Weaver/Picatinny rail, 14-25 in/lbs or 1.5-7.34 Nm (Leupold 14 in/lbs or 1.58 Nm, Warne 25 in/lbs or 2.82 Nm, Badger 65 in/lbs or 7.34 Nm, Vortex 20 in/lbs or 2.26 Nm);

- when tightening screws on a ring and mounting rings on a riflescope’s tube, 15-25 in/lbs or 1.69-2.82 Nm (Badger 15 in/lbs or 1.69 Nm, Leupold 15 in/lbs or 1.69 Nm, Warne 25 in/lbs or 2.82 Nm, Vortex 20 in/lbs or 2.26 Nm), whereby the mentioned torque values of screw tightening apply to all the rings, regardless of the diameter of the ring (25.4 mm, 30 mm, 34 mm, etc.);

- when mounting optics with an integrated rail (SR rail, ZM/VM rail), the recommended torque value of screw tightening is 40 in/lbs or 4.52 Nm.

Problems that can occur when using inappropriate tools

If these tools are not used when mounting the optics and tightening the screws, two things can happen that greatly affect the precision, reliability and life span of the optics:

- the screws are mounted with insufficient torque (even less powerful calibers with a low recoil can cause improperly mounted optics to move since enough inertial force is applied to the optics to make the optics slide forward if the rings are tightened with insufficient torque. There is a great chance of physical damage to the optics’ housing and voiding the manufacturer’s warranty);

- the screws are mounted with too much torque (optics’ housings are made from aluminium, usually the 6061 alloy. In order to reduce weight, they make them with very thin walls, just thick enough to withstand the force needed for mounting of the optics. If too much torque is used on the ring screws, there is a great chance of deformation of the aluminum walls and severe damage to the optics, leading to the voiding of the manufacturer’s warranty).

Conclusion

If we are going to install the optical gadget ourselves, it is recommended to think about purchasing a quality torque driver. It is not worth risking to damage the optics worth 1000 € or more in order to save a few euros. However, if we don’t have enough knowledge and courage to mount the optics, it’s definitely better to leave it to an expert gunsmith.

Don’t own torque driver yet?

I’d like to see the specifics for these products. For example, what sizes of hex and/or star tips do they include?

We are going to expand this article in the future, providing the readers with more details. Are you interested in the hex/star tip size of any specific mount?

I would stick to

Rings – 18 Inch pounds

Base – 25-30 inch pounds

People tend to over torque and bend the scope tubes. They are not steel, even if the rings are steel the weakest link is the scope tube.

What about clamps to a dovetail mount on a Parker Hale Safari in 308W.

Lots of rifles still have factory dovetails.

I enjoyed the article. Back in the day we just mounted the bases and rings as tight as we thought it was needed. Luckily we had no issues at least that I could remember. These days I use a Tipton Ultra to hold my rifles when I am mounting scopes. I bought rail levels and turret levels from FixItSticks as well as a torque kit to make sure I am getting the right torque on all the mounting hardware! I only buy the best rings, bases and rails I can afford and never skimp on something as important as the mounts on a rifle. It drives me crazy when I try someone’s rifle and the crosshairs are canted. I make sure mine are dead level!